- Topsoe’s SynCORTM hydrogen technology will enable ExxonMobil to produce hydrogen at mega scale as well as capture and store more than 98% of its associated CO2 emissions, or around 7 million metric tons per year.

- The facility’s carbon capture process will be delivered by Honeywell UOP

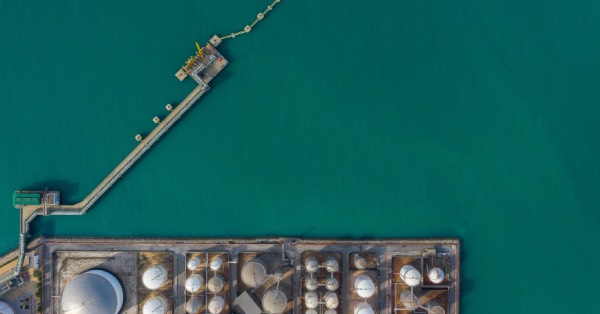

- ExxonMobil’s planned low carbon hydrogen facility will be built at their integratedrefining and petrochemical complex in Baytown at Houston, Texas

- The facility has a targeted production of 1 billion cubic feet of hydrogen per day,making it the largest low-carbon hydrogen project in the world, at planned start-up in 2027-2028.

Topsoe, a global leader in carbon emission reduction technologies, and ExxonMobil, one of the world’s largest energy and petrochemical companies, have signed an agreement under which Topsoe will deliver its industry leading hydrogen SynCORTM technology to ExxonMobil’s planned low carbon hydrogen production facility in Baytown, Texas.

ExxonMobil’s low-carbon hydrogen, ammonia, and carbon capture facility is expected to generate up to 1 billion cubic feet of hydrogen per day, delivering low-carbon fuel to the Baytown olefins plant and other Houston-area facilities. Replacing natural gas with hydrogen at the Baytown olefins plant could reduce the integrated complex’s CO2 emissions by up to 30%.

Elena Scaltritti, Chief Commercial Officer, Topsoe, said:

“We are very excited to support ExxonMobil with our unique technology. Once complete, this ambitious project will result in hydrogen that can be used for low-carbon fuels and chemicals to help meet global net zero targets. We are eager to start working with ExxonMobil and to enable the capturing of massive volumes of CO2 emissions from the hydrogen production.”Dan Ammann, president of ExxonMobil Low Carbon Solutions, said:

“ExxonMobil’s investment in large scale low-carbon hydrogen production shows our commitment to supporting customers in their decarbonization efforts and to reducing emissions at our own operations. The scale of this project is expected to enable up to a 30% reduction in Scope 1 and 2 emissions from our Baytown facility by switching from natural gas as a fuel source to low-carbon hydrogen.”

Facts about low carbon hydrogen and SynCORTM

Low carbon hydrogen is produced by converting natural gas into hydrogen and CO2 in the presence of steam. More than 99% of the associated CO2 can be captured and permanently stored underground.

To produce the large amount of hydrogen needed by ExxonMobil, Topsoe applies its SynCORTM technology, which enable mega-scale hydrogen production as well as cost efficient carbon capture.

To deliver an integrated solution, Topsoe has teamed up with carbon capture technology licensor, Honeywell UOP. As technology integrator, Topsoe guarantees the carbon intensity of the integrated low carbon facility including, hydrogen production and carbon capture.

SynCORTM is Topsoe ́s proprietary technology based on advanced autothermal reforming principles. Supported by 300 years of accumulative, safe operation, SynCORTM is often the preferred technology for mega scale hydrogen production, due to its maturity and low capital and operating costs.