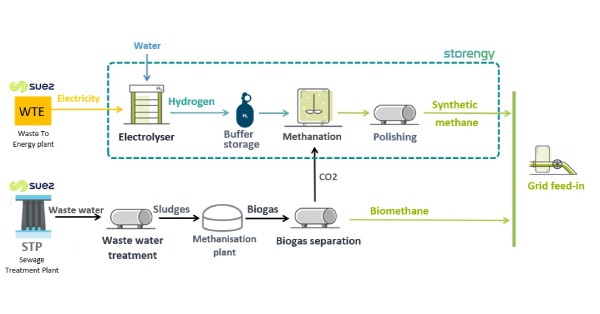

MAN Energy Solutions is to provide at methanation unit for a wastewater treatment plant in Pau, France. A public call for tenders by the urban community of Pau Bearn, Pyrénées – related to the construction of a new sludge-treatment unit for a wastewater treatment plant – has been won by a temporary consortium of companies led by Suez Eau, France and including Storengy, Camborde Architectes, SOGEA/Vinci and EGIS Eau. The new unit will have two main functions:

• the treatment of sludge by anaerobic digestion, which produces a mixture of bio-methane and biogenic CO2

• the conversion of biogenic CO2, a co-product of the anaerobic digestion, along with renewable hydrogen into synthetic methane via power-to-methane.

Arnauld Filancia, President, MAN Energy Solutions France, said: “For MAN Energy Solutions, this project involves converting a mixture of biogenic CO2 and green hydrogen into synthetic natural gas by catalytic methanation. The methanation unit makes it possible to increase the production capacity of the biogas plant by more than 50%. All of the bio-and synthetic methane produced will be injected into the gas network.”

Storengy has entrusted MAN Energy Solutions France with the engineering, supply, transport, installation and on-site commissioning of the methanation unit. The methanation unit will be constructed at MAN Energy Solutions’ site in Deggendorf, Germany, where the company’s competence center for complex reactor systems for synthetic fuel production is situated.

“MAN Energy Solutions offered the best technical solution and serious guarantees to carry out this project, which is why we chose this partner,” said Yan Figarol, Project Manager at Storengy.

Arnauld Filancia concluded: “Everyone agrees that green hydrogen and power-to-X are effective solutions towards reducing our environmental footprint. We are delighted to have the opportunity to demonstrate that power-to-X is technically feasible and economically viable. This installation will perfectly meet major current and future climate challenges.”

How the methanation works

The site’s performance is increased by producing synthetic methane from the methanation of green hydrogen (H2) and carbon dioxide (CO2). The latter, a product of anaerobic digestion (methanisation), is usually released into the atmosphere. The innovative catalytic methanation technology – introduced by Storengy for a world-first on the industrial stage for such an installation – allows the transformation of all the CO2 emitted into synthetic methane, a green renewable gas. This major technological breakthrough has a dual advantage: the additional production in the long-term of 4,400 MWh of synthetic methane per year, and an unparalleled carbon-neutral footprint.

The total bio- and synthetic methane produced by the site will, eventually, be 13,000 MWh per year – the energy equivalent of heating 1,200 homes