The engines and accompanying SCR systems will be supplied direct to Sanmar from the MAN Energy Solutions production facility in Denmark, with a delivery scheduled for December 2022, while vessel completion is planned for Q3 2023.

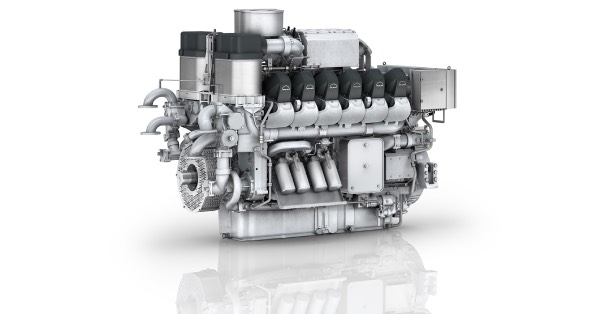

“Svitzer is extremely excited with the new and very innovative TRAnsverse tug design which we have developed in collaboration with Robert Allan Ltd. The compact 26-meter version of the TRAnsverse tug called for ‘short’ TIER III engines. With the MAN 175D engine we believe we have found the right balance between engine size and power requirement. Our experience with this type of engine is good and we recently used this type of engine for two icebreaking tugs delivered last year,” Svitzer’s Chief Operating Officer, Ingrid Uppelschoten Snelderwaard, said.

Hakan Tunç, Engineering Director of Sanmar Shipyards, said: “The excellent collaboration between Sanmar, Svitzer and MAN Energy Solutions’ technical and commercial departments has resulted in optimization at every stage of the development of this innovative TRAnsverse 2600 tugboat design, including its power, crew safety and environmental impact. We are proud to be the builder of this extremely special Svitzer-created and RAL-designed tugboat. We are also happy to try the high speed MAN engine with its SCR solution in this special project.”

Benjamin Andres, Head of High Speed, MAN Energy Solutions, said: “This is just the latest reference for the MAN 175D engine within the tug market sector. It clearly demonstrates that the engine is ideally suited to such a demanding application, where its technical and economical credentials stand it in good stead, while its compactness, performance and operational cost benefits are all seen as key aspects for our customers.”