・ Project part of MHI Group’s effort to expand businesses for the CCUS value chain, utilizing the advanced gas handling technologies of Mitsubishi Shipbuilding.

・ With the acquisition of this AIP, MHI Group will focus on developing and offering the technologies needed to bring LCO2 carriers to the market.

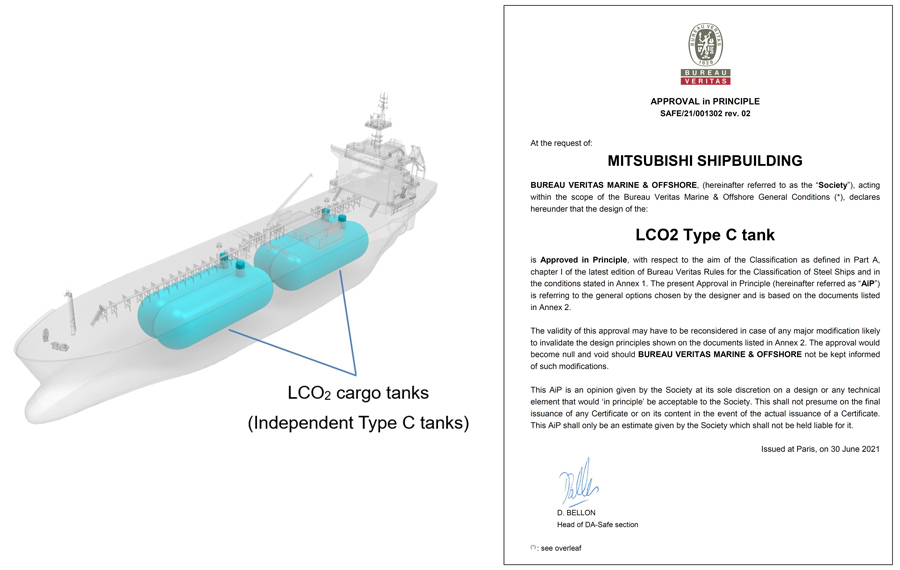

Mitsubishi Shipbuilding, a part of Mitsubishi Heavy Industries (MHI) Group, has been granted Approval in Principle (AIP)(Note1) from the French Classification Society Bureau Veritas (BV) for a cargo tank system to be mounted in a liquefied CO2 (LCO2) carrier.

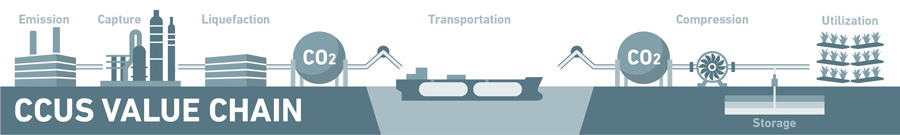

MHI Group is pursuing a range of strategic measures to strengthen businesses related to energy transition, and establishing a CO2 ecosystem is a key part of that effort. Further, carbon dioxide capture, utilization, and storage (CCUS) is attracting attention worldwide as an effective means to achieve decarbonization. LCO2 carriers play a pivotal role in transporting CO2 from its emission sources to storage sites or facilities for utilization, and demand for these vessels is expected to increase in the future. Mitsubishi Shipbuilding is responding to this demand by actively pursuing development and commercialization of LCO2 carriers.

LCO2 carriers transport liquefied CO2 gas as a liquid in a low temperature, high pressure state. Accordingly, independent Type C tanks as defined by the IGC Code(Note2) are typically used for the cargo tank system. A structural design based on standards for pressure containers is required when using a Type C tank. There are various structural types for these tanks, including cylindrical, bilobed, and trilobed. A further important factor is to select a steel material for the LCO2 tanks with exceptional high strength and low temperature properties.

Looking ahead to the future, Mitsubishi Shipbuilding previously conducted studies on CO2 carriers in 2004 as a participant in the International Energy Agency (IEA)’s Greenhouse R&D program, utilizing the advanced techniques for structural analysis, material evaluation, gas handling, and other expertise it has accumulated from the construction of liquefied gas carriers (liquefied petroleum gas (LPG) and liquefied natural gas (LNG) carriers).

Going forward, with this acquisition of an AIP for the LCO2 cargo tank system, MHI Group will continue to develop and offer a wide range of technologies related to the LCO2 carriers essential to building a CCUS value chain, and contribute to the realization of a decarbonized society.

- 1Approval in Principle (AIP) indicates that a certification body has reviewed the basic design, and confirmed that it meets the technical requirements and standards for safety. The inspection of this system was conducted based on the IGC Code that applies to marine vessels that transport liquefied gas in bulk, and BV’s ship classification regulations.

- 2The International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC Code) is an international regulation stipulating the safety requirements for ships that transport LCO2, LNG, or other liquefied gases as cargo in bulk.

AIP for the LCO2 carrier cargo tank

Video of LCO2 carrier