MAN Energy Solutions’ paper-industry vacuum systems registered a record level of incoming orders in the tissue sector in the first quarter of 2021 where a total of 11 contracts were signed with customers across all global regions.

“We are proud of the large market impact our TURBAIR® technologies for tissue machines have had worldwide. We have been able to strengthen our presence, not only in countries in which our vacuum systems already experience widespread use but also in markets such as Central and South America, and Australia where we see great potential for future growth,” said Manfred Dobler, Head of Sales Paper Industry at MAN Energy Solutions.

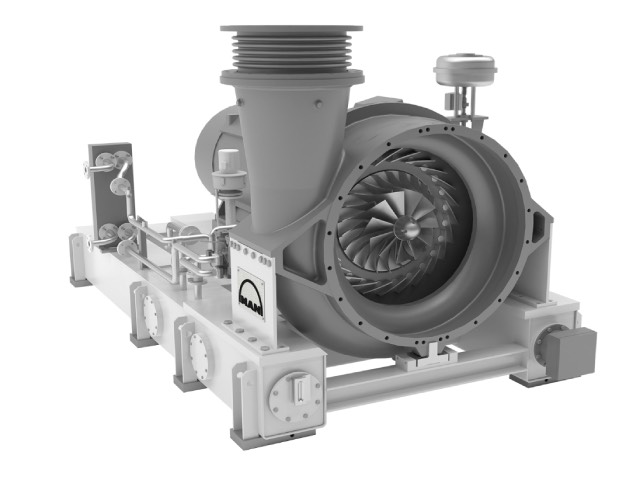

He continued: “Our customers appreciate the availability of MAN employees for on-site visits, the robust design of our machinery, and their low-maintenance operation. The high levels of customer satisfaction over the decades has led to the presence of well over 1,000 TURBAIR® vacuum systems worldwide.”

The global demand for cardboard and tissue products increased by 6% in 2020. Along with continuous population growth, the effects of the Corona crisis have also sparked a rise in demand for hygiene items such as facemasks. Vacuum systems facilitate dewatering during the manufacturing process for paper, cardboard and tissue products.

ABC Tissue Paper PTY Ltd. in Sydney recently marked a first for Australia with an order for a vacuum blower type RT 56-1 for a tissue-paper machine. Simultaneously, MAN Energy Solutions reports gaining a stronger foothold in markets such as the USA, Mexico, Turkey, Poland and Hungary where TURBAIR® vacuum blowers are already in use.

Asian paper and tissue market

There has also been a higher demand for vacuum blowers for cardboard-production systems. In China, manufacturers such as Asia Pulp and Paper (APP) and Liansheng Pulp & Paper have opted for MAN technology for their respective plants in Qinzhou (Guangxi Province) and Zhangpu (Fujian Province). The scope of delivery for these projects includes up to two multi-stage RC and up to two single-stage RT blowers, respectively.

Japan Steel Works (JSW), a corporation operating in the steel, energy and machine industries based in Tokyo (Japan), has transferred MAN Energy Solutions the property rights including all documentation material for 24 vacuum systems used in the paper industry. As a result, MAN personnel will in future take care of the overhaul of the vacuum systems, including their inspection, cleaning and assembly, repair and supply of spare parts, as well as analysis and optimization of the machinery.

After China and the USA, Japan represents one of the largest paper markets in the world. Taken together, the three countries’ production accounts for more than half of all global paper-production. “By taking over the entire after-sales business in Japan, we will also be able to increasingly establish ourselves on the Japanese paper and tissue market and, consequently, tap the full potential for new TURBAIR® orders,” said Romain Bayère, Omnicare Manager at MAN Energy Solutions.

Manfred Dobler added: “Today, the paper industry is facing the challenge of significantly reducing its CO2 footprint. This is why numerous cardboard and tissue manufacturers are replacing their systems equipped with water-ring pumps with energy-efficient and environmentally friendly MAN vacuum systems. Compared to conventional water-ring vacuum pumps, TURBAIR® systems require up to 60% less energy and can be operated without water. Additionally, it is possible to reuse the hot exhaust-air in the energy cycle using a heat exchanger, leading to a further reduction in overall energy consumption of up to 80%.”