A well-known shipowner with a ‘colorful’ brand recently had a change of heart on the value of the painter system as a tool for safer boat launching and recovery, after early stage operations led it to re-evaluate and request a quick turnaround on the installation of the Vestdavit solution.

A fast ferry that recently entered service using a competitor’s davits was subsequently retrofitted with a painter line and boom solution from Vestdavit, after initial boat launch and recovery operations proved below the owner’s expectations.

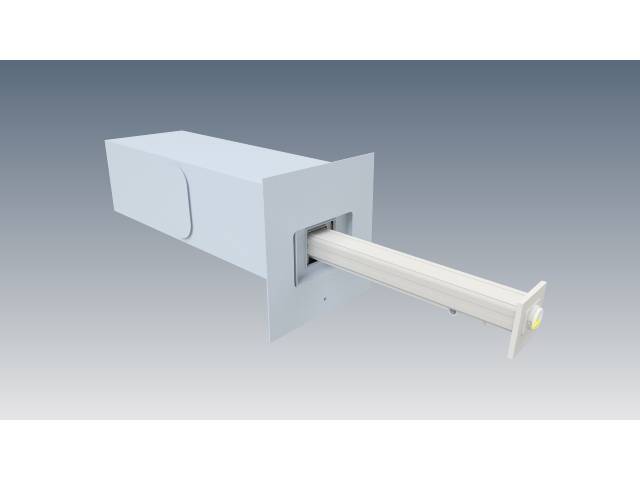

Bjørnar Dahle, Vestdavit Sales & Business Development Director, outlines the issue. “Used with a painter line that connects to a hook in the bow of the crew boat, the painter boom ensures that the boat runs parallel to the vessel during the launching and recovery operation. By allowing it to pick up the painter line without veering towards the ship`s side.”

Vestdavit Area Sales Manager Martin Sundgot Hansen picks up the tale behind the recent painter boom retrofit episode, although he is unwilling to point the finger when it comes to competing equipment.

“When the ship was under construction, we had discussions with the builder about the painter system but for one reason or another the decision was handed down that the installation would continue using a competitor’s davit solution, without a painter boom. Not long after the ship went into service, the customer got back in touch to say there had been hard lessons following delivery. The MOB-boat had to be handled at such a height that there were impacts against the ship side during launch and recovery. Not only did crew feel unsafe – the MOB-boat was also damaged.”

Sundgot Hansen says the owner made it known that not only did the new installation need to be standalone, feature its own power supply and offer an electrical interface for remote painter boom control by the davit operator; it also needed to be delivered fast.

“We had to come up with an adapted version of an existing telescopic painter boom design that could work for their situation, with only 11 weeks for design work, manufacturing and delivery.” Further challenges emerged to coincide with the short stays common in the fast ferry market, although in this case a timely maintenance layover provided the opportunity to deliver and install the new painter boom within the schedule.

“Of course, in painter booms as in everything else, the customer is always right,” adds Dahle. “This is simply an opportunity to highlight that, when Vestdavit says it delivers telescopic and rotatable painter booms in all shapes and sizes, with shock absorbers, remote control and automated tensioning, it can include occasions when the customer exercises the right to change its mind.”