Norwegian marine coatings provider Jotun has announced the launch of Hull Skating Solutions (HSS), a break-through in proactive cleaning, offering shipowners an always clean hull in the most challenging operations.

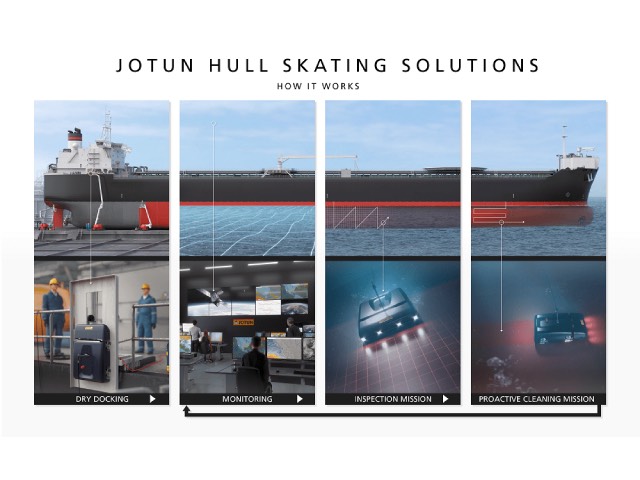

Jotun Hull Skating Solutions is offering high performance antifouling, proactive condition monitoring, inspection and proactive cleaning, high end technical service, and performance and service level guarantees. HSS provides individual proactive condition monitoring services tailored for each vessel, using a proprietary algorithm and big data to accurately predict fouling development and cleaning schedules.

With a comprehensive range of guarantees and service level agreements available, HSS helps to solve the problem of biofouling that shipowners and operators face. According to Jotun, if all ships in challenging operations converted to HSS, a CO2 emissions reduction of at least 40 million tons per year would be possible.

A primary component of Jotun Hull Skating Solutions is the onboard Jotun HullSkater, the first robotic technology that has been purposely designed for proactive cleaning. In combination with the premium SeaQuantum Skate antifouling and a set of services, the Jotun Hull Skating Solutions will help ship operators combat early stages of fouling, significantly reduce fuel costs, CO2 emissions and the spread of invasive species.

The HullSkater removes individual bacteria and biofilm before macro-fouling takes hold. This not only delivers peak performance, and unlimited idle days for shipowners, but minimises the need for reactive cleaning, cutting costs, environmental risk and optimising fleet flexibility. The HullSkater stays on the hull by the force of its magnetic wheels, each equipped with electric motors for propulsion and steering. The vehicle has several cameras and sensors and a specially designed motorised brush to keep the hull free from fouling without causing damage to the hull coating. The vehicle is connected to the operator’s control centre through an umbilical and can be operated remotely for vessels anywhere in the world with 4G coverage. Inspection and proactive cleaning of a hull will normally take around 2 to 8 hours depending on size and condition.

The HullSkater removes individual bacteria and biofilm before macro-fouling takes hold. This not only delivers peak performance, and unlimited idle days for shipowners, but minimises the need for reactive cleaning, cutting costs, environmental risk and optimising fleet flexibility. The HullSkater stays on the hull by the force of its magnetic wheels, each equipped with electric motors for propulsion and steering. The vehicle has several cameras and sensors and a specially designed motorised brush to keep the hull free from fouling without causing damage to the hull coating. The vehicle is connected to the operator’s control centre through an umbilical and can be operated remotely for vessels anywhere in the world with 4G coverage. Inspection and proactive cleaning of a hull will normally take around 2 to 8 hours depending on size and condition.

“Bio-fouling is a big challenge for the shipping industry,” said Geir Axel Oftedahl, business development director in Jotun. “It increases frictional resistance leading to speed loss and greater fuel consumption, while at the same time increasing the risk of the transfer of aquatic invasive species. It is a burden to the industry, and our planet, and demands decisive action.

“That was our starting point in the conception of HSS – a desire to create a definitive solution to this pressing issue, one that wouldn’t just deal with the problem, but rather prevent it. That is what hull skating achieves.

“Vessels are often faced with unpredictable operations, with erratic idling periods and varied operational profiles that make the selection of antifouling problematic, even for the best coatings. And once fouling grows the impacts are immediate, and damaging, with poor hull and propeller performance accounting for around one tenth of the world fleet’s energy consumption. This can make a massive impact on any owner’s bottom line.”