Hempel’s solution for underwater hulls can achieve up to 2.5% in fuel savings and can be applied during routine dry-doc

Key messages

- The SeamFlow weld fairing system for ship hulls can reduce vessel fuel consumption by up to 2.5% and help owners and operators meet emission reduction targets

- In one five-year dry-dock cycle SeamFlow can reduce carbon emissions by 12,000 tonnes and bring fuel savings of up to $1.8 million

- The patented SeamFlow system is a simple way to reduce costs and meet environmental targets, without extending dry-dock time

- After dry-dock, Hempel can use out-of-dock data to calculate fuel savings impact, helping to quantify savings delivered to customers

World-leading coatings company, Hempel A/S, is showcasing its unique new solution, SeamFlow, for the first time in Asia at Sea Asia in Singapore.

The world’s first seam fairing solution for ship hulls is designed to reduce friction on the underwater area of vessel hulls and can reduce fuel consumption by up to 2.5%. Over a one five-year dry-docking cycle it can also save up to 12,000 tonnes of carbon emissions and $1.8 million in fuel costs.

-

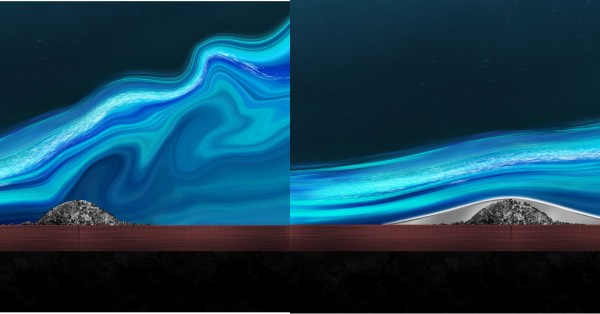

SeamFlow is a complete system of coating, application tools and dedicated service, designed to reduce the friction created as a ship’s hull sails through water. By smoothing the welding seams created when the steel sheets of a ship’s hull meet, friction can be significantly reduced

A ship’s hull has around 5 kilometres of weld seams, and although the welds protrude by only 3-9 millimetres, their dragging effect on a vessel’s operation adds up to a significant amount.

-

Mads Raun Bertelsen, Marine Data and Technology Director, Hempel -

Mads Raun Bertelsen, Marine Data and Technology Director at Hempel, says:

“SeamFlow has been available for application on vessels since last year and, with the positive results seen on all applications until now, Hempel is delighted to share the possible positive impact of SeamFlow at Sea Asia this week. By reducing the drag created by the welds on a ship’s hull we are able to deliver considerable fuel savings to industry and also support owners’ and operators’ emission-reduction pathways.”

SeamFlow is applied during routine dry-docking after the hull has been coated with one coat of anti-corrosive primer. Two SeamFlow applicator teams then apply the modified epoxy using specially developed equipment to the welding seams. Hempel-approved experts are onsite to guide the application and carry out quality checks. After 10-12 hours the specialised epoxy coating will be dry and ready for the final tie-coat and top-coat as usual. Hempel also offers in-service performance monitoring to help quantify the customers’ return on investment.

Nikhil Lakhiani, SeamFlow Solution Owner at Hempel, says:

“SeamFlow is a smart and simple solution for ship owners to reduce costs and meet environmental targets without the need for any significant additional downtime. The

application can be easily accommodated in the dry-docking schedule, and if planned well, becomes a smooth and integral part of dry-dock operation.”

SeamFlow is compatible with all Hempel products, which offer further efficiencies and cost-saving opportunities.