France-based BIO-UV Group has strengthened its position in the global ballast water treatment system (BWTS) market with the addition of 3D laser scanning and modelling to its BIO-SEA engineering and design services.

The new service follows increased shipowner demand for turnkey BWTS retrofit solutions capable of reducing or negating BWTS installation time in drydock.

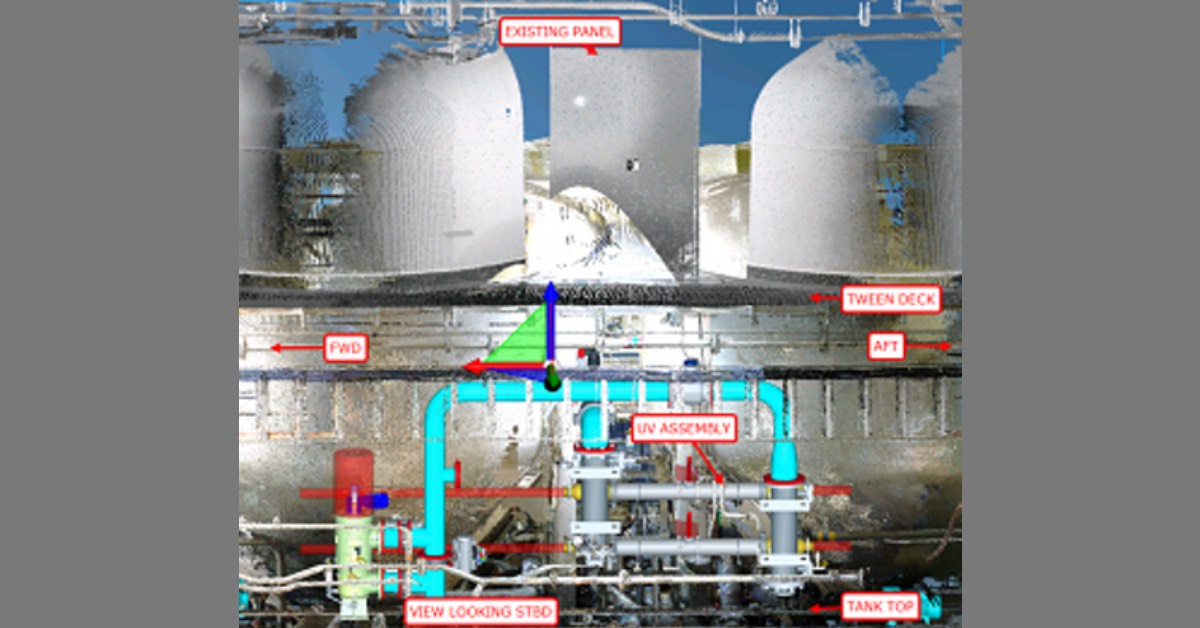

The digital scanning of a ship’s compartment generates a 3D image from which BIO-UV Group engineers can find the optimum site for its BIO-SEA system and develop more detailed engineering to expedite class approvals and installation.

Florian Cortes, Technical Director – BIO-SEA, BIO-UV Group, said: “By providing a complete BIO-SEA BWTS retrofit package that includes everything from 3D scanning, and modelling to detailed design and commissioning, shipowners need only deal with one or two suppliers rather than several.”

Maxime Dedeurwaerder, Business Director – BIO-SEA, BIO-UV Group, added: “By offering a free-of-charge feasibility audit and competitively priced 3D scanning we can support complete ballast water treatment projects end-to-end. This is a significant benefit for shipowners looking at ways of installing a ballast water treatment system without taking the vessel out of service.”

Due to the current spike in freight rates, BIO-UV Group is fielding more enquiries for in-service installations using dedicated BIO-SEA ‘flying squads’.

“Of course, this adds more to the total cost,” said Dedeurwaerder, “but at least the ship remains in service, earning money. This is a real hot topic at the moment.”

According to Dedeurwaerder, there is a noticeable trend for shipowners looking to work with “a limited number of business partners during a retrofit project, and to be fully supported along that process”.

Coinciding with the introduction of digital modelling services, BIO-UV Group has also updated all versions of its UV technology-based BIO-SEA systems to ensure compatibility with GPS data acquisition.

“This is a new feature we are providing in anticipation of possible future regulatory requirements,” Dedeurwaerder said.

“The GPS Data is simply the registration in the log of the system of the vessel GPS position when a ballasting operation is performed. By crossing with all other input data, various analyses will be possible, although at first this addition aims to anticipate a possible IMO regulation update relating to the localisation and tracking of ballasting operations.”

BIO-UV Group will be exhibiting its recently launched medium flow rate M-Series BIO-SEA at Booth 4202 of the Europort 2021 trade show, which takes place at Rotterdam’s Ahoy Centre between 2nd and 5th November.

Joining its low-flow L-range, the BIO-SEA M-Series is a multi-lamp reactor designed specifically for flow rates of up to more than 2100m3/h. The compact, low-height design makes installation easier than medium flow range BWTS in the market.