TRUCONNECT ®Wire Rope Monitoring, the newest addition to Konecranes’ digital ecosystem, provides customers with real-time insight into the condition of a wire rope while avoiding shutdowns and operation interruptions. It supports Konecranes’ broader mission to provide smart technology and a digitally enabled customer experience to improve the safety, productivity and sustainability of our customers’ operations.

“Through remote monitoring, customers will know the condition of their wire ropes in an instant, at any time. This helps reduce the risk of load drop and other safety issues, and also assists with planning for maintenance, repairs or replacement,” said Esa Kukkola, product manager for Konecranes Service.

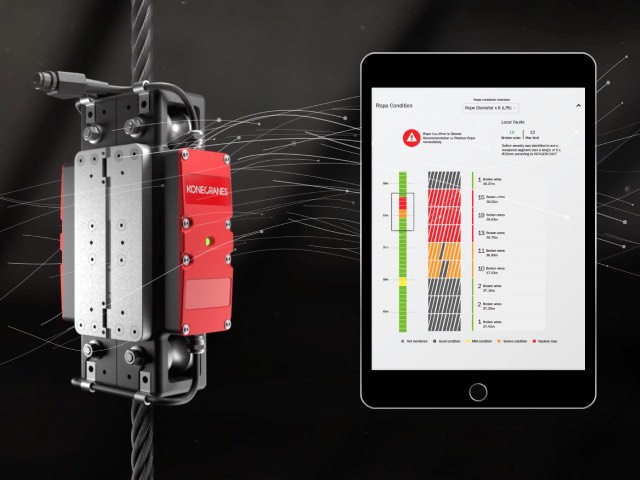

Specialized and patented sensors using magnetic-inductive leakage technology are clamped around the wire rope of a crane. If the rope condition deteriorates below set limits, customers receive a safety alert through text or email, allowing for a quick response to rope issues.

Additionally, the sensors reveal visible exterior defects as well as internal defects that aren’t detectable with a visual inspection. Wire rope defects can develop and progress quickly due to metal fatigue, Kukkola said. “The ability to continuously monitor the wire rope is especially useful for the larger cranes used in automotive and paper industries or anyone using process cranes 24/7.”

Kukkola also noted the cost-saving benefits of Wire Rope Monitoring. When traditional magnetic non-destructive testing is performed to analyze the condition of the internal wires, a specialist has to perform the inspection and the crane has to be shut down for the day.

“Shutdown time means production interruptions and production losses that can cost customers thousands or even tens thousands of dollars,” Kukkola said. “As long as whole rope is run through the sensor each work cycle, there’s no shutdown needed to inspect the rope. Even when crane usage varies significantly, TRUCONNECT Wire Rope Monitoring provides continuous knowledge of the condition of the wire rope.”

A strong focus on customers and commitment to business growth and continuous improvement make Konecranes a lifting industry leader. This is underpinned by investments in digitalization and technology, plus our work to make material flows more efficient with solutions that decarbonize the economy and advance circularity and safety.