Remote Approach Allows Jack-Up Production to Continue Despite Virus Constraints

A pioneering remote survey for steel certification at a steel mill by ABS has enabled work on two self-elevating drilling units (SEDU) at Lamprell Energy Ltd, UAE to continue despite COVID-19 restrictions.

Lamprell ordered 8855 MT of steel for two SEDUs from Arcelor Mittal Nippon Steel Mill in Gujarat but travel restrictions caused by COVID-19 mitigation measures made it impossible for ABS to certify the steel at the mill in person, potentially delaying the project.

In what is understood to be an industry first, ABS proposed a remote survey option, with ABS surveyors in Mumbai certifying the steel with data provided by the mill, and production continuing of the SEDUs continuing on schedule.

“I am proud of how we have innovated to respond to a real-world challenge and support our customers in the delivery of this key material despite the unprecedented challenges created by the virus. This is typical of ABS’s agile and responsive approach,” said Matt Tremblay, ABS Senior Vice President Global Offshore. “ABS is leading the way in remote survey and this case highlights the breadth and flexibility of our remote capability, which delivers genuine operational advantages for our clients.”

Lamprell’s Chief Operating Officer, Hani El Kurd said: “ABS’s remote inspection solution has been an excellent mitigation solution to maintain the quality assurance and schedule demands of our projects. It also ties up well with our digitalization strategy which starts with our own processes and those of our service providers and suppliers.”

Wim Van Gerven, Director and Vice President – Operations, ArcelorMittal Nippon Steel India Ltd, said: “ AM/NS is proud to have partnered with ABS to conduct remote survey and certification of steel during lockdown due to the COVID-19 global pandemic. This demonstrates our ability to use technology for business continuity. The development of an online certification process has facilitated AM/NS to supply steel to customers even in the most difficult times.”

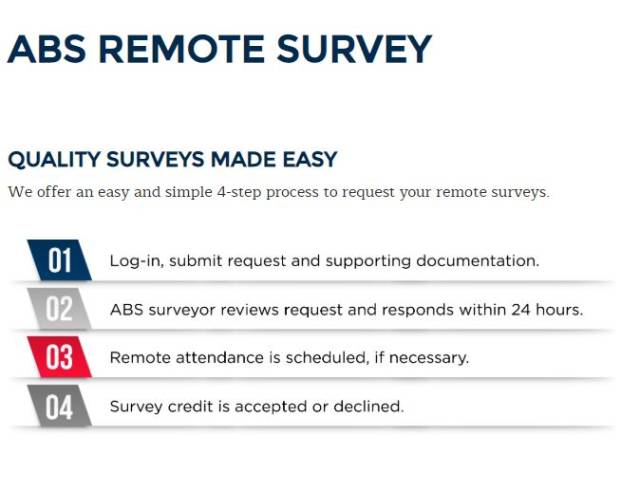

ABS has significantly expanded its remote survey capability and is now able to conduct almost all classification annual surveys remotely on eligible vessels and has made its remote survey and audit services available to equipment and materials manufacturing clients all over the globe.

Find out more about ABS’s Remote Survey program here.