Kongsberg Maritime is proud to introduce Health Management to the Vessel Insight portfolio of applications. With Health Management, ship owners can monitor onboard equipment via one unified interface and predict failures through early detection of abnormal behaviour. This holistic facility, whilst often cited as a key functionality for smart ships, has not been readily available to date, making this launch a milestone in the development of smart technologies for the maritime sector.

Due for launch in August, the new Health Management application will initially support Bergen engines, Kongsberg Maritime’s low-pressure hydraulic winches, and rotating machinery such as KONGSBERG and third-party thrusters, pods, shaftline and auxiliaries. Additional equipment will be added to the system in a planned roll-out over the following months, making Health Management applicable to vessels across the maritime industry.

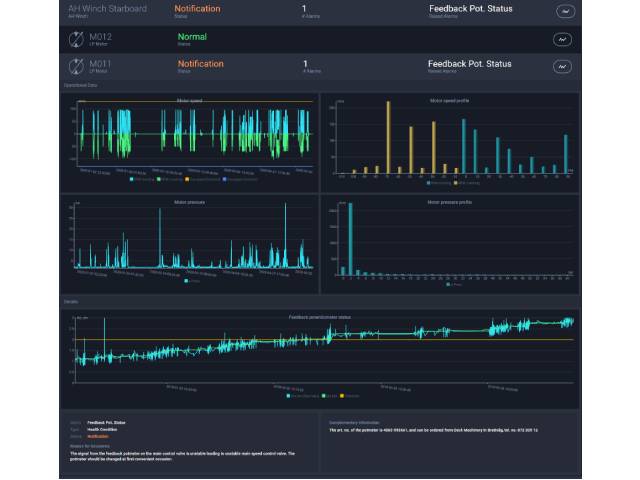

Health Management helps customers to mitigate the capital and operational risks associated with the failure or unplanned maintenance of critical machinery. By continuously reporting equipment condition, Health Management facilitates intelligent maintenance planning, increasing reliability and reducing operational expenditure by limiting vessel and equipment downtime. This keeps vessels working and extends equipment lifetime through early identification of abnormal wear or suboptimal operation; in some cases, this may allow servicing to be performed only when needed.

Jan Chirkowski, VP Analytics & Fleet Operations at Kongsberg Maritime, explains: “By continually appraising machinery condition, Health Management allows customers to spot the early onset of a failure and continue operation with the affected equipment under observation. Maintenance needs can be planned in advance when most convenient for the customer, spare parts ordered, and vessel downtime scheduled as necessary. Any downtime is minimised, and the vessel is returned to operation as swiftly as possible. The net result is to maximise profitability.”

Kongsberg Maritime is uniquely placed to lead the market in this area, drawing on exclusive knowledge of its own vast portfolio of equipment – combined with certified monitoring of KONGSBERG and third-party machinery – to provide holistic condition monitoring solutions for all equipment critical to a customer’s operations and deliver it on one unified platform.