As a pioneer of the electrolysis technology applying to BWTS, Techcross has been successful in the market with 3,762 systems installed and delivered with its prominent Electro-Cleen System (ECS). Apart from major advantages such as no fine filtration required, small footprint with installation flexibility and competitive price with worldwide AS service network, another big contribution to the success is providing innovative BWTS installation solutions for various type of vessels to minimize the CAPEX and OPEX through continuous R&D.

One of the examples is After Peak Tank (‘APT’) treatment of tankers using the BWTS installed on main ballast pipeline. As the main BWTS treats ballast uptake for APT, our customers could save over U$100Kby not installing the separate BWTS for APT. The other example is engine room solution for the tankers with submerged pumps (such as MR tanker) and by installing non ex-proof model in the engine room instead of ex-proof model in hazardous area, our customers saved 20% of system price as well as 30% of installation costs. These two solutions eliminate the needs for separate BWTS for APT and as a result, Techcross provides BWTS for APT free of charge.

Treatment of APT with BWTS located in hazardous area

DNV has investigated and approved the only one ballast water treatment system (BWTS) on a tanker with APT used for ballast water in Nov. 2018. In case only one BWTS full flow electrolysis system is to be installed in hazardous area it can normally only serve ballast water(‘BW’) in the cargo area. Water taken onboard to safety area (e.g., APT) is not allowed to pass the treatment unit located in hazardous area before entering safe area. However, DNV has evaluated the following sequence as an equivalent solution:

- a) Uptake of untreated water to APT in location A. (All cargo BW tanks must have treated water)

- b) Transport to location B

- c) Transfer of BW in APT over deck through non-return connections to the treatment system in hazardous area

and further to an empty BW tank in cargo area - d) Hold the water in cargo area for the required hold time (according to TA certificate)

- e) Discharge BW using neutralization as required by type approval.

[Flowdiagram using APT]

DNV also stated that “If the treatment system includes a filter, the backflush water contains living organisms which is not allowed to be discharged in a different location from where it origins. When applying treatment as specifying in item c above, the backflush water is not allowed to be discharged overboard. This water must be collected in a separate tank and later delivered to an onshore treatment facility. Filtering the water during uptake to APT using a separate filter in safe area is not considered equivalent to the process type approved, since the organisms not separated by the filter will grow in size and number before second treatment is applied. However, having a separate filter will probably help to reduce particles and organisms allowing less backflush events and less water to collect during transfer of water from APT to cargo area for treatment by the second filter and electrolysis in the cargo area.” which makes full flow system with filter not feasible for the APT treatment solution.

Techcross ECS without filter can treat APT untreated seawater through the system in hazardous area and further to an empty BW tank in cargo area and then discharge after minimum holding time of 4 hrs. (Not applicable on USCG TA). The system with minimum holding time of longer than 24 hours may delay and intervene the operation of vessel at the port or during drydocking.

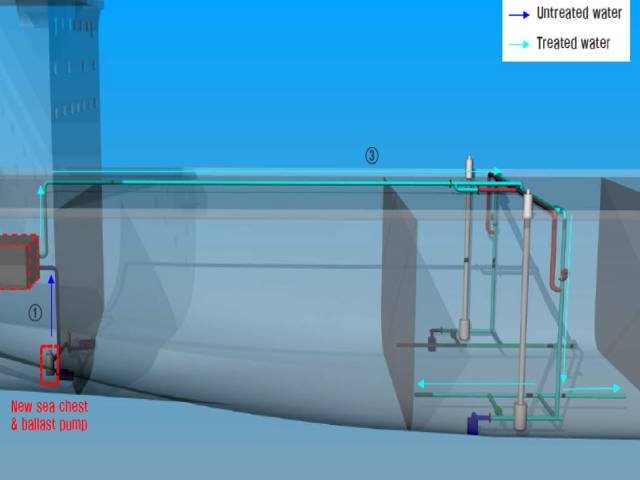

BWTS engine room installation solution for the tankers with submerged ballast pumps

In case of tankers with submerged pumps, an explosion proof type full flow BWTS is generally installed in a specially designed room on the deck which involves safety concerns and high cost of installation.

Techcross’ patented installation solution makes it possible to install non-explosion proof type BWTS in the engine room by utilizing existing Fire/GS pump(s) or adding ballast pump(s) for ballasting operation while using the submerged pumps for de-ballasting operation only. This patented solution provided a great benefit to ship owners/operators in terms of safety and BWTS CAPEX and installation costs. This solution has been applied to 50+ NBs MR tankers at Korean shipyards as well as retrofits.

[ Diagram of engine room installation solution]

EPA’s proposed Vessel Incidental Discharge National Standards of Performance would apply to non-recreational, non-Armed Forces vessels that are 79 feet in length and above. For ballast water, the proposed regulations would also apply to small vessels (less than 79 feet in length) and fishing vessels of all sizes. Small vessels transit voyage will also require BWTS and the smallest unit ECS-150 with compact skid mounted ‘one fits all’ system would be suitable for the needs. Techcross is currently working on R&D for minimizing footprint and cost targeting lowest system price and will continue to provide innovative installation solution to all